Toward a better future for people and cars.

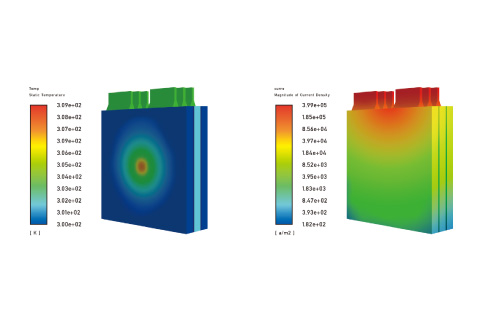

Support lithium-ion battery performance improvement.

Electric vehicles are expected to solve environmental and resource issues. However, there are issues such as driving distances and charging time, and the development of higher performance lithium ion batteries is required. In that area, simulations are used to reduce development costs and time. Battery shape and material combinations are verified in software, issues such as safety and performance are eliminated in advance, and then verification is performed on the actual product. We always work closely with our engineers to continuously improve our software. As global demand continues to grow, high-performance electric vehicles are required. Our CAE technology plays an important role in the development of all-solid-state batteries that are essential for achieving this.

Pioneer the Toyota Group's Future with creative CG.

In the world of video content and manufacturing, the use of CG is more advanced than ever. We have cultivated the technology to create beautiful and accurate content, such as high-definition images, video, VR, AR, and configurators through CG production of cars. Going forward, we will apply this technology to various fields to provide unprecedented user experiences in a wide range of fields, such as the automotive industry, entertainment, person-to-person communication. Our future possibilities are endless.

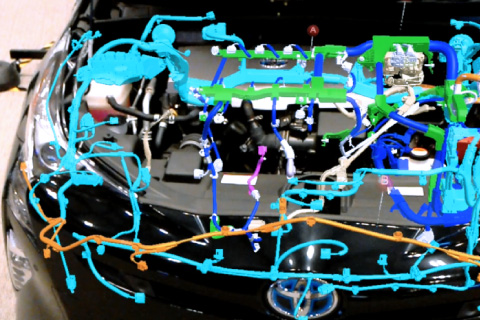

In order to further improve productivity,

we are using MR for next-generation manufacturing.

MR is an abbreviation of Mixed Reality, a technology that overlays the real and virtual worlds. Various digital technologies are used in automotive development, Toyota Systems has contributed to shortening development periods and reducing costs by applying MR to production technology. In equipment reviews, digital data from new equipment and development vehicles are superimposed on the actual production line to check installability and workability. Because assembly work can be experienced in virtual space, it can also be determined on the spot whether there are issues such as worker's operating position. Even in detailed work, what was previously checked against drawings can be done by superimposing digital data to proceed quickly and reduce mistakes. In this way, MR can provide solutions for decisions that are difficult to make using only the data or actual testing, and lead to a new era of manufacturing.

Take on the challenge of Toyota-style Agile development

to build new development methods.

In today·s fast-moving world, change is also required in development systems. Until now, we have developed according to the "Toyota System Development Management" book. Furthermore, in order to make the system more resilient to change and more practical, Toyota developed a large-scale system using the Agile method for the first time. In the past, it took two to three years for creation of design documents, prototyping, and testing. However, during that time the world changed, and by the time the project was completed the requirements had already changed. But, according to Agile, design documents are not written, the systems are just made. That way, changes can be incorporated into the requirements. Specifications are included in the code, and low-code tools are used for which code doesn't need to be written. To emphasize a sense of speed, one Toyota team member would also participate to teams of five or six. A decision-maker is also present in each team so that prompt decisions can be made on the spot. Discussions between the teams are lively, and the walls of the dedicated rooms are filled with post-it notes. Scrum, which is Agile's main development method, is actually based on the Toyota Way/ Toyota Production System. We believe this initiative does not contradict Toyota Motor Corporation's past, rather it is derived of the great things from Toyota's track record. When faced with challenges, we continued to take on those challenges with confidence. We will further refine the Toyota-style Agile method, clarify it as a new development method, and expand it throughout the group.

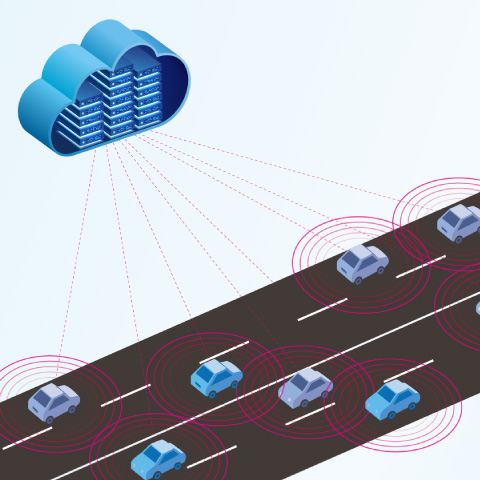

Prevent accidents via Al that predicts flat battery using big data.

Big data is used in every field. Cars are now connected to networks, and at Toyota Systems we are working to improve user convenience through data analysis. A huge amount of driving data is collected daily by Toyota Motor's data center. By processing and analyzing that data and having Al learn it, we have developed a system that notifies the dealers in advance of dead batteries. We consider how to handle test data to achieve what we want to do, create formulas, adjust thousands of variables, and build Al. There are major differences in Al effectiveness depending on how it is used. We are working on improving performance while continuing dialogue with engineers on site. As data continues to increase in the future, we will create a safer vehicle society, such as by way of more accurate notifications for each vehicle type.